Product parameter

product details

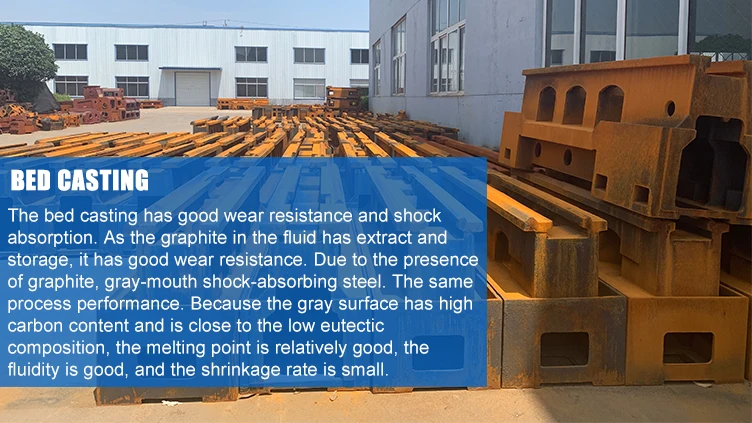

①The machine body casting has good wear resistance and shock absorption. Since graphite in cast iron is good for lubrication and oil storage, it has good wear resistance. Similarly, due to the presence of graphite, gray cast iron has better shock absorption than steel.

②Good process performance. Due to the high carbon content of gray cast iron, which is close to the eutectic composition, the melting point is relatively low, the fluidity is good, and the shrinkage rate is small. Therefore, it is suitable for casting of complex structure or thin-walled bed castings.

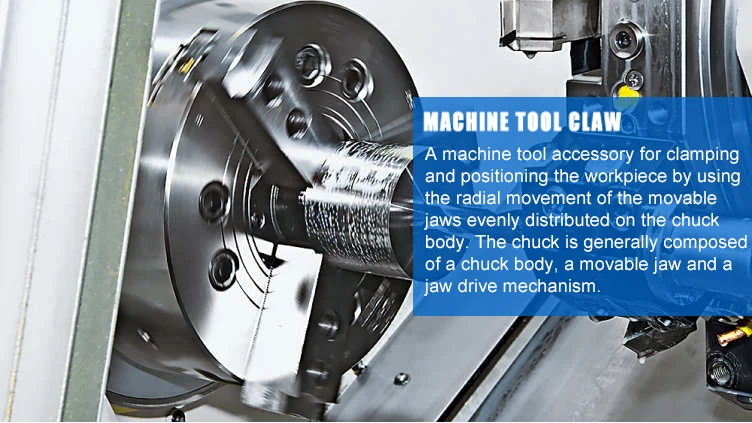

A chuck is a machine that uses surrounding objects on a machine tool. Using the movement of the movable jaws on the chuck, the computer disk device and the positioning of the machine tool accessories. The chuck device is composed of a chuck device and a movable device. Claw and claw drive mechanism consists of 3 parts

The tool post is a very important part of the CNC lathe. According to its function, the number of tools that can be installed on the tool post of CNC lathes is generally 4, 6, 8, 10, 12, 20, and 24. Some CNC lathes can install more tools.

The system is a very important part of the CNC lathe. OPPAIR CNC lathe can replace the system you need according to your needs, such as FANUC, Siemens, etc. Our standard configuration is the Guangshu system

According to your needs, you can choose different CNC machine tools, but we are all integral bed, you can rest assured in terms of stability, the linear guide of the inclined bed adopts the Taiwan brand guide, and the flat bed is made by our factory's own grinding and milling machine. Made, after high temperature quenching experience

We have exported to more than 50 countries in the world. We have customers from many countries, and they praise our products. Just like you who are watching our machines, you will soon become a member of the OPPAIR family. Welcome to cooperate with us. !

CNC machine tool is the abbreviation of digital control machine tool, which is an automatic machine tool equipped with a program control system. The control system can logically process a program with a control code or other symbolic instructions, decode it, express it with coded numbers, and input it into the numerical control device through an information carrier. After arithmetic processing, the numerical control device sends out various control signals to control the action of the machine tool, and automatically process the parts according to the shape and size required by the drawing.

The CNC machine tool has solved the problem of complex, precise, small batch, and multi-variety parts processing. It is a flexible, high-performance automatic machine tool and represents the development direction of modern machine tool control technology.

Shandong OPPAIR Machinery Manufacturing Co.,Ltd is a domestic AAA-level enterprise with high-quality service and integrity in Linyi, Shandong, whch is committed to the innovation of machining technology and solutions to promote the progress of China's manufacturing level. The main products are two series, CNC machine tools and screw air compressors.

OPPAIR currently has more than 300 employees. OPPAIR adheres to and implements the ISO9001 quality system and on-site 6S management mode for a long time. Every link is meticulous and strictly manages every process from production. All products have passed mechanical safety certification, and have advanced technology and stable performance. They have won many national and provincial awards.

More than 15 Years of production and sales experience has enabled OPPAIR to better understand customer needs. At present, OPPAIR products are sold in more than 30 countries around the world, and there are OPPAIR agents in Europe, America, the Middle East, and Southeast Asia. Choose OPPAIR, choose high quality and durable.

FAQ

Q1: Are you factory or Trade Company?

A1: We are factory of Linyi, Shandong. We have our own trade company for export.

Q2: How long is your product warranty?

A2: Usually the whole machine is guaranteed for one year

Q3: What voltage can you provide?

A3: We can support 220V/380V/400V/415V/440V, 50HZ/60HZ

Q4: How long is your delivery time?

A4: Normally 2 month. If your order is urgent, we can arrange production in advance.

Q5: How to pay?

A5: We support T/T wire transfer. Or delivery pay by Alibaba.

Q6: What should I do after maintenance?

A6: Our machines are easy to maintain and operate in the later stages. We support the sale of later maintenance parts, and later customers only need to operate according to our prompts. For inexperienced customers, we can provide video guidance.

Contact us